Tractor Fender Durability and Sustainability: A Farmer's Guide

Protecting your investment and the environment are intrinsically linked. This guide explores the often-overlooked world of tractor fenders, examining their importance, material choices, and pathways toward enhanced sustainability.

The Unsung Heroes of the Farm: Why Tractor Fenders Matter

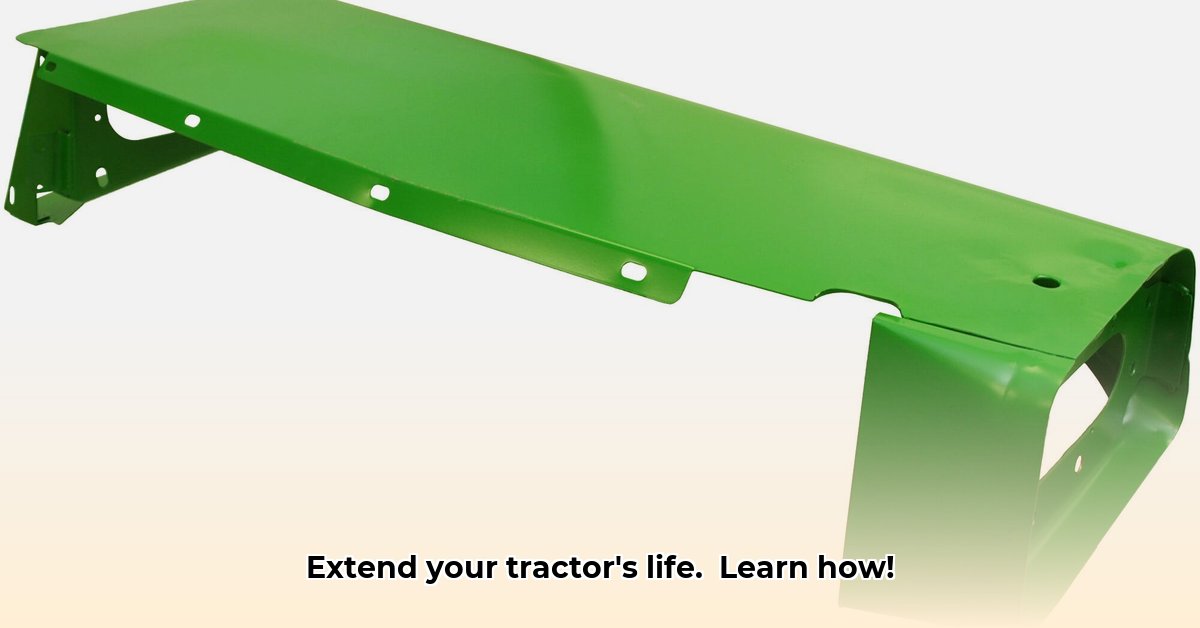

Your tractor is your livelihood. Maintaining its peak condition is paramount, and this includes components you may overlook, such as fenders. These aren't mere metal flaps; they're protective shields safeguarding vital parts from damage. A well-protected tractor translates to fewer breakdowns, reduced downtime, and substantial savings in repair costs. Consider fenders the unsung heroes of your farm, silently contributing to extended lifespan and improved efficiency. Replacing fenders is costly; therefore, selecting durable, long-lasting options is crucial. Don't underestimate their impact – how much downtime have you experienced due to fender damage?

Tractor Fender Materials: Weighing the Options

Choosing the right fender material is a balancing act, impacting both performance and environmental impact. Steel offers robust strength and affordability, a time-tested choice for many farmers. However, its heavier weight might slightly reduce fuel efficiency. Aluminum, conversely, is lighter, potentially boosting fuel economy and simplifying installation. Yet, it's more expensive upfront and may not withstand impacts as effectively as steel. Composite materials represent a newer option, aiming to combine the strength of steel with aluminum's lightweight properties. Their long-term performance and sustainability, however, require further investigation.

The sustainability aspect introduces further complexity. Comprehensive data on each material's entire lifecycle – from manufacturing energy to disposal – remains limited. Further research is crucial to fully understand the environmental footprint of each option, encompassing manufacturing processes, transportation emissions, and end-of-life recyclability. What are the true long-term costs associated with each material?

Customization: Tailoring Tractor Fenders to Your Specific Needs

Just as farming practices vary, so too should your tractor fenders. Fenders are not one-size-fits-all; they come in various sizes and configurations to complement your specific tractor model. Extensions broaden coverage, enhancing protection, while step plates improve safety and access. Well-fitted fenders improve visibility, mitigating accident risks. Investing in custom-fit fenders safeguards your tractor's protection and enhances operational safety. How much does improved visibility contribute to your overall safety?

The Sustainability Gap: A Need for Transparency

A major obstacle in sustainable agriculture is the scarcity of data on the environmental effects of tractor fenders. Comprehensive life cycle assessments (LCAs) are crucial for accurately evaluating the sustainability of different materials and designs. These LCAs assess the entire lifespan, from raw material extraction and manufacturing to use and disposal. Without this data, decision-making is significantly hampered. Industry-wide transparency is essential, including energy consumption during manufacturing and transport, material durability, and ultimate recyclability. What specific data points are currently lacking in the life cycle assessments of fender materials?

Actionable Steps Towards a More Sustainable Future

Addressing the sustainability of tractor fenders requires collaboration. Here’s how key stakeholders can contribute:

- Manufacturers: Publicly disclose material composition; commission LCAs on existing products. Invest in research and development of eco-friendly materials (recycled, biodegradable). Design fenders for easier disassembly and component recycling.

- Farmers: Regularly inspect fenders for damage; prioritize timely repairs. Consider the total cost of ownership (including environmental impact) when purchasing new equipment.

- Suppliers: Explore sustainable manufacturing and sourcing practices. Partner with recycling facilities to manage end-of-life fender disposal.

- Regulators: Encourage stricter regulations on material disclosure. Develop policies to support responsible disposal of farm equipment parts.

How to Choose Sustainable Tractor Fenders for Eco-Friendly Farming

Key Takeaways:

- Tractor fender selection is crucial for both operational efficiency and environmental responsibility.

- Fender material significantly impacts lifespan and environmental footprint.

- Sustainable choices consider the entire fender lifecycle, from manufacturing to disposal.

- Collaboration among farmers, manufacturers, and policymakers is essential for promoting sustainable practices.

The Unsung Heroes of Sustainable Farming: Tractor Fenders

Tractor fenders, while often overlooked, play a vital role in efficient and eco-friendly farming. They protect your tractor, improve visibility, and, when chosen wisely, contribute to a smaller environmental footprint. Therefore, selecting sustainable tractor fenders for eco-friendly farming is a crucial consideration. How can farmers balance cost-effectiveness with long-term environmental sustainability?

Durability: The Foundation of Sustainability

Durable fenders protect against damage, reducing the need for replacements. Frequent replacements increase waste and costs. A long-lasting fender minimizes environmental impact. What factors determine a fender's lifespan? Material selection is paramount.

Material Matters: Weighing the Pros and Cons

Let's examine common fender materials:

| Material | Pros | Cons | Sustainability Considerations |

|---|---|---|---|

| Steel | Strong, durable, readily available | Heavy, prone to rust, requires more energy to produce | Consider recycled steel options; assess end-of-life recycling potential. |

| Aluminum | Lightweight, corrosion-resistant, recyclable | More expensive than steel, can be damaged more easily | High recyclability is a plus; evaluate energy consumption during production. |

| Composites | Customizable, lightweight, potentially high strength | Can be expensive, recyclability varies depending on composition | Investigate the specific composite's recyclability and embodied carbon. |

Material choice must account for strength, weight, and cost-effectiveness. Remember, a sustainable choice considers the entire life cycle—from manufacturing to disposal.

Customization: Finding the Perfect Fit

Customizable fenders offer advantages such as a snug fit, maximizing protection and visibility, and therefore extending lifespan.

The Sustainability Gap: A Need for Transparency

The agricultural sector needs more data on the total environmental impact of fender materials. LCAs are essential for comparing materials and designs. Without standardized LCA data, making truly informed sustainability choices remains challenging.

Actionable Steps: A Collaborative Approach

- Farmers: Demand more sustainable options from manufacturers. Prioritize the long-term cost and environmental impact of equipment choices.

- Manufacturers: Invest in research and development of sustainable materials and manufacturing processes. Publish transparent LCA data on products.

- Suppliers: Promote sustainable sourcing and recycling of fender materials.

- Regulators: Encourage sustainability standards for agricultural equipment. Incentivize the use of eco-friendly materials.

Collaboration will drive positive change. Investing in sustainable tractor fenders benefits both the planet and efficient farming practices.